Introduction:

Long shaft pumps are vital components in various industries, facilitating efficient fluid transportation over extended distances. In this article, we will explore the features, functionality, and significance of long shaft pumps in enhancing efficiency and reliability in fluid transportation applications.

Understanding Long Shaft Pumps:

Long shaft pumps are mechanical devices designed to move fluids, such as water, oil, or chemicals, by converting mechanical energy into hydraulic energy. These pumps consist of a motor or engine, a long rotating shaft, and an impeller that creates fluid flow.

Functionality of Long Shaft Pumps:

Long shaft pumps serve several important functions:

a. Fluid Transport: These pumps efficiently move fluids from one location to another, overcoming resistance and delivering them to desired destinations.

b. Pressure Generation: By utilizing impellers, long shaft pumps generate the necessary pressure to ensure fluid flow through pipelines or channels.

c. Versatility: Long shaft pumps can handle various types of fluids, making them suitable for diverse applications in industries such as agriculture, manufacturing, and infrastructure.

Key Features of Long Shaft Pumps:

a. Long Shaft Design: The extended length of the pump's shaft allows it to reach deep into fluid sources or transfer fluids across considerable distances.

b. High Efficiency: Long shaft pumps are designed to operate with high efficiency, minimizing energy consumption while fluid transportation capabilities.

c. Durability: These pumps are constructed with robust materials, ensuring resistance to corrosion, wear, and tear, thus extending their operational lifespan.

d. Flexibility: Long shaft pumps can be customized to accommodate specific flow rates, pressure requirements, and fluid properties, catering to unique application needs.

Importance of Long Shaft Pumps in Fluid Transportation:

a. Improved Efficiency: Long shaft pumps enable the efficient and continuous movement of fluids, reducing downtime and optimizing overall productivity.

b. Reliable Performance: With their sturdy construction and reliable operation, long shaft pumps ensure consistent fluid flow, minimizing disruptions and maintenance requirements.

c. Cost-Effectiveness: By streamlining fluid transportation processes and reducing energy consumption, long shaft pumps contribute to cost savings in the long run.

d. Versatile Applications: These pumps find applications in various sectors, including irrigation, municipal water supply, oil refineries, and wastewater treatment plants.

Applications of Long Shaft Pumps:

Long shaft pumps are widely used in numerous industries and applications, including:

a. Agricultural Sector: These pumps facilitate efficient irrigation, ensuring the proper distribution of water to fields and crops.

b. Industrial Processes: Long shaft pumps are employed in manufacturing plants for fluid transfer and circulation in chemical processes, cooling systems, and more.

c. Municipal Water Supply: They play a vital role in transporting water from reservoirs or treatment plants to households and businesses within a city or town.

d. Mining Operations: Long shaft pumps are utilized to drain water from mines and transport fluids during extraction and processing operations.

Conclusion:

Long shaft pumps are indispensable in fluid transportation applications, offering enhanced efficiency, reliability, and versatility. With their ability to transport fluids over extended distances and withstand diverse operating conditions, these pumps contribute to improved productivity, reduced costs, and seamless operations in various industries.

English

English عربى

عربى

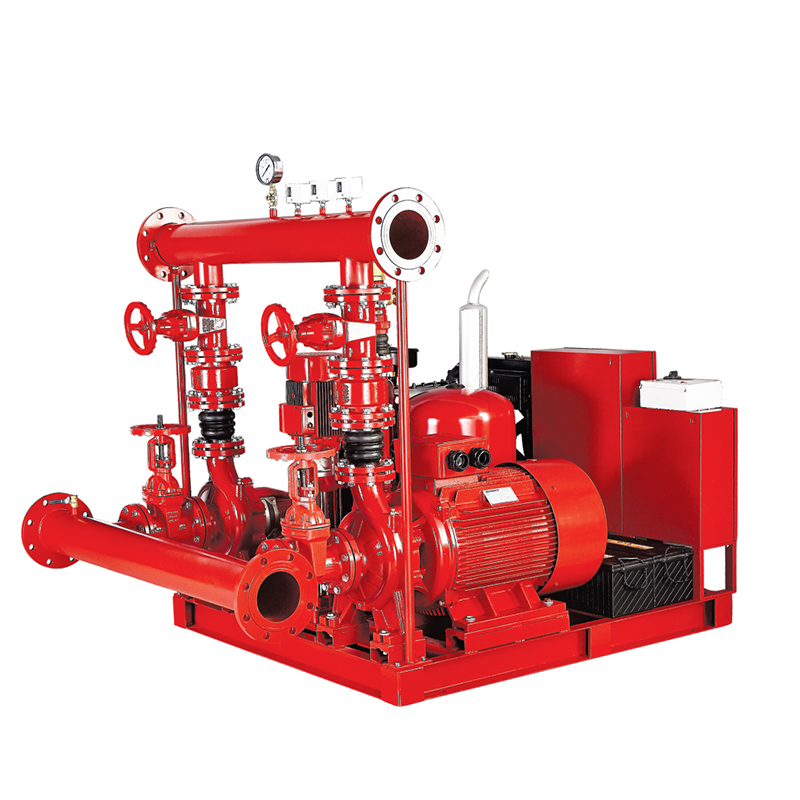

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump